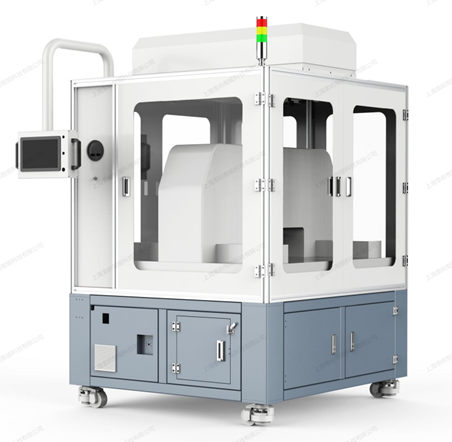

Narrow slit extrusion, precise empowerment: high-precision narrow slit flat coating equipment leads industrial innovation

In the modern manufacturing industry that pursues ultimate performance, the precision of the coating process directly determines the upper limit of cutting-edge products. Among them, slot die coating technology, with its excellent performance, has become the preferred solution for preparing ultra-thin and uniform functional films. The slot die coating equipment from Shanghai Suoyu Intelligent Technology Co., Ltd. has pushed the coating thickness to the molecular level of tens of nanometers and stably controlled the areal density uniformity within ±2%, providing a reliable process foundation for numerous high-tech fields.

Technical core: The precision of slot plate coating

Slot die coating is a predictive coating technology. Its principle is that the slurry, driven by a precision metering pump, passes through a slot die with a special internal cavity structure and is extruded uniformly at a stable flow rate, then transferred onto a steadily advancing flat substrate, forming a layer of wet film with precise thickness and uniform distribution.

The key to achieving ultra-thin coating of just a few nanometers and uniformity within ±2% lies in the extreme control over every step of the entire process:

Ultra-precision slit die: This is the heart of the equipment. The mechanical processing accuracy of its lip gap needs to reach the micrometer level or even the submicrometer level. The internal cavity design (such as a hanger-style design) ensures consistent pressure of the slurry across the full width of the die, which is fundamental for achieving lateral uniformity.

Stable Intelligent Feeding System: Integrating high-precision screw pumps or gear pumps, online defoaming devices, and a constant temperature system, it ensures that the slurry supplied to the die head is bubble-free, has stable viscosity, and maintains precise flow rate, eliminating fluctuations from the source.

Zero-disturbance motion platform: Utilizing a precision flat platform supported by air bearings and driven by linear motors, it ensures a constant gap and stable speed between the substrate and the die lip during the coating process. This forms the foundation for achieving excellent longitudinal uniformity.

Online real-time thickness measurement and closed-loop control: Serving as the brain and eyes of the equipment, the system conducts 100% online scanning inspection of the coated film through β-ray or X-ray thickness gauges. The data is fed back to the central controller in real time, dynamically adjusting the pump speed, platform speed, or die gap to form a precise closed-loop control, actively counteracting any external interference.

Core composition: meticulously crafted system integration

A high-precision slit flatbed coating equipment is mainly composed of the following major systems:

Coating unit: The core components include ultra-precise slit die, back pressure adjustment mechanism, and leveling system.

Feeding unit: includes slurry tank, metering pump, filter, defoamer, and thermostat.

Motion and substrate processing unit: high-rigidity flat platform, vacuum adsorption system, cleaning device.

Detection and control system: online thickness gauge, PLC, industrial computer, and professional coating software algorithm.

Application field: Empowering high-end manufacturing and cutting-edge scientific research

With its contact-type and high-precision characteristics, the slit plate coating equipment is indispensable in the following fields:

New energy battery: It is the absolute main process for preparing lithium-ion battery electrode sheets (positive and negative electrodes). The uniformity of its coating directly affects the energy density, safety, and cycle life of the battery.

High-end display and semiconductor: used for coating OLED luminescent layers, photoresists, PI substrates, etc., it is a key link in the manufacturing of flexible displays, microelectronic devices, and integrated circuits.

Functional thin films: Preparation of ultra-thin protective films, optical adhesives, high-barrier packaging films, etc., which are widely used in consumer electronics, automotive, and packaging industries.

Cutting-edge new materials: It serves as an ideal platform for sample preparation in laboratory research and development, as well as pilot production, for nanomaterials, graphene, perovskite solar cells, and more.

Application advantages: Creating core value for customers

Choosing high-precision slit flat coating equipment means occupying the commanding heights of technology:

Extremely high coating consistency: The uniformity of ±2% significantly enhances product yield and batch stability, laying the foundation for building a high-end brand.

Broad process window: By adjusting parameters, it can accommodate a wide range of slurries from low viscosity to high viscosity, offering strong flexibility in application.

With a high material utilization rate, as an estimated amount coating method, there is almost no excess slurry waste, which brings significant economic benefits, especially when coating precious materials.

Clean and pollution-free: The slurry is directly transferred from the die to the substrate in a closed system, avoiding external contamination and suitable for products with high cleanliness requirements.

Conclusion

The slot plate coating technology, with its rigorous physical principles and precise engineering implementation, has become a benchmark in the field of high-precision coating. It is not only a manufacturing process, but also a bridge that transforms new materials and designs from blueprints into real products. As the technology industry continues to move towards miniaturization and high performance, high-precision slot plate coating equipment will surely continue to empower innovation and drive the future.

Please first Loginlater ~